Julian Esper

Julian Esper

Project description

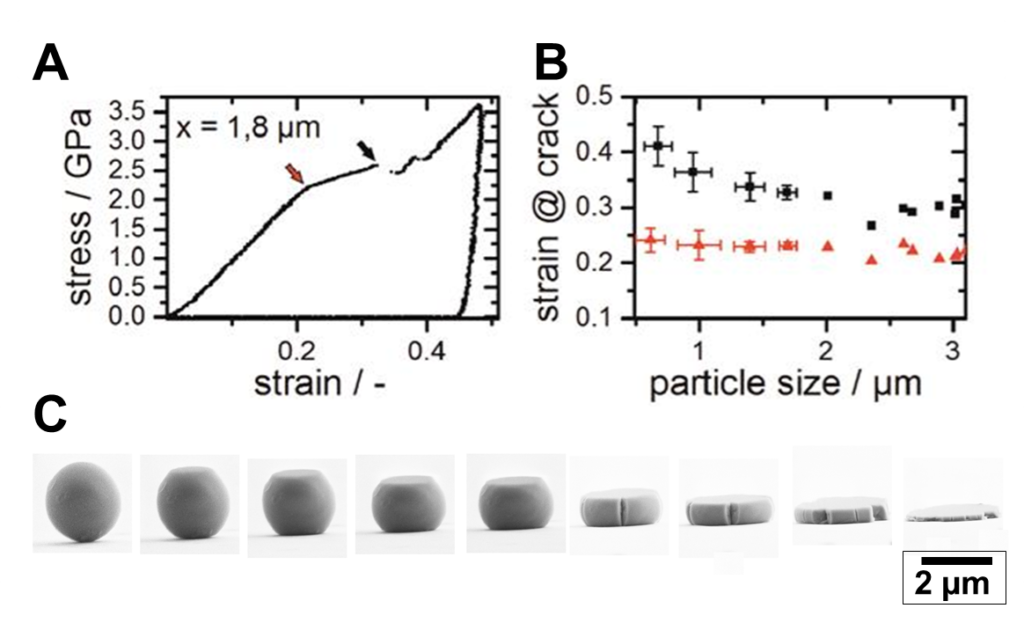

The mechanical response of homogeneous bulk materials to external stimuli can be described by the constitute laws of continuum mechanics. However, for example, SiO2 glass exhibits a brittle-to-ductile transition at smaller particle sizes (< 800 nm) resulting in unique mechanical properties. The addition of different glass network modifiers can influence the macroscopic material response dramatically and has not been investigated on the (sub-) micron level. Especially in the field of particle technology, where single particle properties govern the final product properties, the mechanical deformation behavior if individual micron-sized particles is of great interest [1,2].

Within this context, structurally and morphologically well-defined particulate glass systems are characterized over a broad particle size range by complementary in situ compression experiments in a scanning electron microscopy. Mechanical testing is performed in a SEM- supported manipulation device [3] which allows for a statistical evaluation of different mechanical quantities such as Young’s modulus, breakage probability and brittle-to-ductile transition.

Fig. 1: Stress-strain curve of a soda lime glass particle (SiLi Beads, Fa. Sigmund Lindner, Germany) (A) and particle size dependant mechanical behavior of soda lime glass (B). Corresponding SEM images of a 1.8 µm soda lime glass particle at different stages of compression (C).

References

[1] J. Paul et al., Advanced Powder Technology 25 (2014) 136.

[2] J. Paul et al., Powder Technology 286 (2015) 706.

[3] S. Romeis et al., Review of Scientific Instruments 83 (2012) 95105.