Eva Preiß

Dr.-Ing. Eva Preiss

Project description

Progress in the field of miniaturization of electronic and electromechanical devices has made thin films become essential for a broad range of products. The study and precise characterization of their mechanical properties have therefore become an important industrial challenge. Moreover, there is widespread scientific interest in the deformation behavior of thin films. Size effects on mechanical properties have been evidenced and are in many cases not yet fully understood. Whereas most of the studies so far deal with size effects on strength, this project focuses on effects on fracture toughness. By testing freestanding metallic films the fracture properties of samples with their critical dimension well below one micrometer can be determined without being influenced by any substrate.

A few studies already reported very low fracture toughness for freestanding metallic films, typically an order of magnitude lower than that of their bulk counterpart [1, 2]. However, a generalized explanation of the extremely low fracture toughness of thin films is still missing. Within this project, different influences such as film thickness, microstructure, strength and residual stress are systematically investigated. The scope is to identify dominant factors affecting the fracture toughness of thin films and to gain a better understanding of the pronounced size effect.

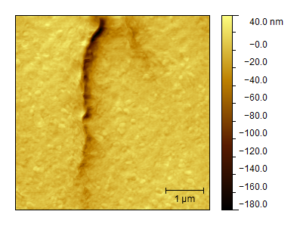

For mechanical testing, a custom-built bulge test setup is used. In order to determine the fracture toughness of the film, a narrow notch acting as pre-crack is introduced into its center by FIB (focused ion beam) milling. Subsequently, the membrane is loaded until failure [3]. The setup also allows for in-situ testing in an AFM (atomic force microscope) [4]. In-situ observations of the deformation in front of the crack tip (see Fig. 1) and of the crack propagation are used to complement the quantitative data with information on the evolution of the plastic zone and active deformation mechanisms.

Fig. 1: AFM image of the deformation in front of a crack tip in a freestanding polycrystalline gold thin film of 150 nm thickness.

References

[1] H. Hirakata et al., Int. J. Fract. 192 (2015) 203.

[2] H. Hosokawa et al., Thin Solid Films 516 (2008) 6444.

[3] B. Merle and M. Göken, Acta Mat. 59 (2011) 1772.

[4] E. Schweitzer and M. Göken, J. Mater. Res. 22 (2007) 2902.