Aviral Vaid

Aviral Vaid, M.Sc.

Project description

Understanding dislocations and dislocation-interface interactions is of fundamental importance for the development of alloys with improved mechanical properties. Common approaches to increase the strength of alloys are solid solution, precipitate and grain boundary strengthening [1]. Atomistic simulations have played an important role in understanding the atomic scale processes underlying these strengthening mechanisms [2]. Until now, most such simulations studies are performed on materials with both, simple crystal structures and simple (unary or binary) compositions. Many alloys, however, contain routinely more than four elements and are characterized by the presence of precipitates with complex crystal structures. In this project, we study atomic scale deformation mechanisms in both, crystallographically complex and compositionally complex crystals and microstructures.

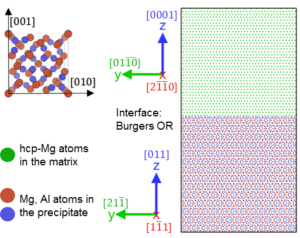

As example for a crystallographically complex crystal, we study Mg17Al12, which is the most common intermetallic phase found in the Mg-Al alloy system. It has a complex bcc-like crystallographic structure with a unit cell containing 58 atoms, see Fig. 1. In collaboration with experimental work (Prof. Göken), we study dislocations in Mg17Al12 and the interaction of dislocations in the Mg matrix with Mg17Al12 precipitates.

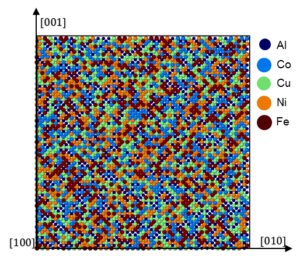

As a special representative for chemically complex alloys with simple crystal structure, we study fcc-based high entropy alloys (HEAs). These are a novel class of alloy systems with five or more elements at near equiatomic composition [5,6]. It is assumed that the high configurational entropy in these alloys stabilizes the single phase despite a significant energetic cost as the disordered arrangement of atoms implies large atomic-scale lattice distortions. HEAs have been shown to possess interesting mechanical properties, such as low weight to strength ratio, combination of high strength and toughness, etc.[5,7]. The aim of this project is to understand the strengthening mechanism in HEAs by studying dislocation motion in such structures and provide information for mesoscale models (Prof. Zaiser, WW9). An example for a model fcc-HEA is AlCoCuNiFe shown in Figure 2.

Figure 1: (left) Crystallographic structure of the complex intermetallic Mg17Al12; (right) Interface between Mg-Mg17Al12 in the Burgers orientation relationship between the matrix and the precipitate.

Figure 2: Atomic arrangement in a model fcc alloy AlCoCuNiFe to study dislocation motion in single-phase high entropy alloys.

References

[1] G.E. Dieter, Mech. Metall. 186 (1986).

[2] E.B. Tadmor et al., Modeling Materials (2011).

[3] D. Amberger et al., Acta Mater. 60 (2012) 2277.

[4] M.X. Zhang et al., Scr. Mater. 48 (2003) 647.

[5] M.-H. Tsai et al., Mater. Res. Lett. 2 (2014) 107.

[6] B. Cantor, Entropy 16 (2014) 4749.

[7] Y. Zhang et al., Prog. Mater. Sci. 61 (2014) 1.